CASE STUDY:

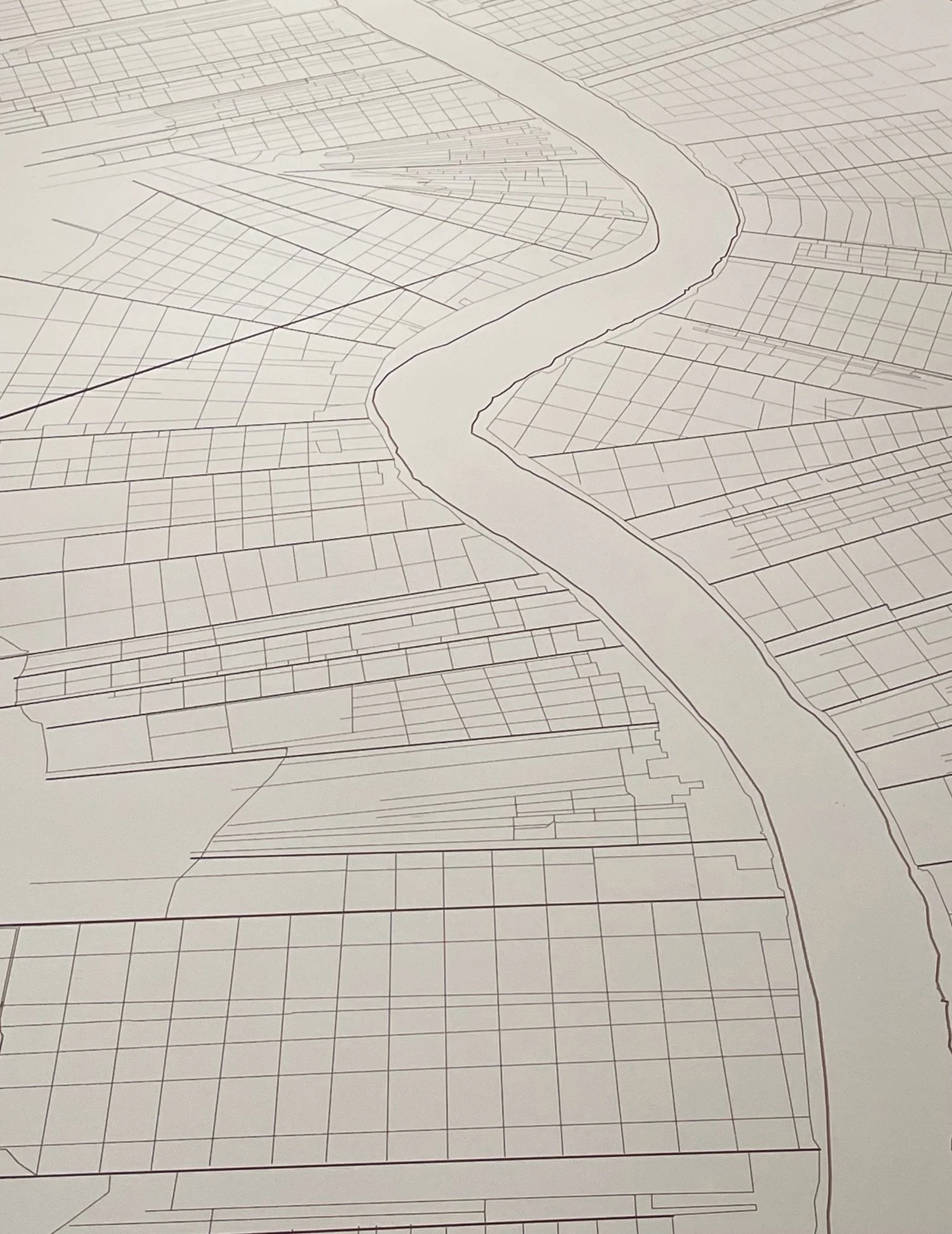

3D Map Installation

Leading Complex Multi-Phase Projects Through Strategic Pivots

THE CHALLENGE

Systems Coordination, Strategic Vendor Management, Multi-Phase Fabrication and Integration

Over five months, I led a complex fabrication and technical integration project: a 23' x 9' laser-cut map table with 3 projections. I knew it would be challenging but I didn't anticipate just how much creative problem-solving it would require. I coordinated multiple external vendors, internal teams, and cross-institutional stakeholders while keeping both the artistic vision and technical precision intact.

Strategic Planning & Vendor Management

The project had two main phases: external fabrication followed by internal technical integration. What made this particularly complex was that each phase involved completely different stakeholders—fabricators, artists, technical teams, and institutional decision-makers—all with their own priorities and approval processes.

I found myself constantly translating between different "languages," helping fabricators understand artistic intent while explaining technical constraints to creative stakeholders.

The technical specifications themselves presented unique challenges. I needed to identify and coordinate with precision manufacturers while ensuring their capabilities aligned with the project, artistic vision, and budget constraints.

Vendor Evaluation & Selection:

Conducted comprehensive vendor analysis for specialized Laser/CNC fabrication capabilities

Evaluated technical capabilities against artistic requirements

Managed vendor relationships through daily communication protocols

Created vendor performance monitoring and quality assurance frameworks

Requirements Analysis:

Worked with vendor to translate stated needs from the artists vision into workable technical specifications

Identified key timeline dependencies between fabrication and in-house production phases, and set milestones accordingly

Ensured that finished product from vendor would meet rigorous museum quality standards - effectively my vendor was producing an art object

Created detailed project milestone tracking and projected deadlines based on changing parameters from curators and artist

Process Optimization & Strategic Pivots

Mid-project, our original fabrication approach became cost-prohibitive, forcing a complete strategic pivot. I had to quickly evaluate alternative solutions—shifting from the requested laser cut to CNC fabrication, and from expensive architectural panel substrates to cost-effective MDF.

This involved working constantly with our fabricator to ensure receipt of proper files, review proofs with the artist collective and ensure final production would meet budget and deadlines. This constraint introduced timeline pressures as multiple project dependencies had to be recalibrated simultaneously—including the on-site installation — of which this piece was only a part.

Cost Optimization:

Shifted from expensive architectural panels to painted MDF substrate

Negotiated new fabrication with vendor for optimized pricing

Achieved 50% cost reduction while maintaining artistic integrity

Created reusable cost-benefit analysis framework for future projects

Quality Assurance:

Established design iteration protocols for continuous refinement

Created centralized file modification and version control storage system

Implemented real-time problem-solving processes between vendor, artist, curator, and other stakeholders

Ensured and maintained focus on rigorous quality standards through manufacturing and timeframe changes

Cross-Functional Team Leadership

My approach was to create detailed requirement maps that outlined technical specifications alongside budget parameters and timeline dependencies. This helped me work with our vendors systematically and communicate trade-offs clearly to stakeholders.

When presenting options, I always included the "why" behind each recommendation, helping decision-makers understand how choices would ripple through the rest of the project.

Stakeholder Management:

Managed daily communication with multiple external fabricators

Coordinated cross-institutional stakeholder approvals

Balanced artistic vision with technical and budget constraints

Created transparent communication channels for complex decision-making

Multi-Phase Project Coordination:

Phase 1: External fabrication management and quality control

Phase 2: Internal technical integration and multimedia implementation

Seamless handoff protocols between external and internal teams

Resource allocation optimization across project phases

Technical Integration Leadership:

Led internal team through complex construction and technical implementation

Coordinated integration of CNC-fabricated elements with projection systems

Managed precise technical specifications for multimedia components

Created documentation for complex technical assembly processes

Technical Innovation & Problem Solving

The integration of physical and digital elements required the map panels to be in-house and fully installed well before our deadline, giving the install team time to set up and troubleshoot the projection system. I maintained communication with the vendor during production while ensuring all projection system details were ready and waiting once the maps were installed. I created documentation linking timelines and workloads to help both vendor and internal teams stay on track, preventing deadline errors and ensuring smooth functionality without costly rework.

Manufacturing Process Innovation:

Created workflow optimization for physical-digital integration

Established quality control protocols and aesthetic requirements for precision CNC manufacturing outcomes

Built knowledge management systems for complex technical processes

Technical Integration:

Team designed integration system for 3 vertical projectors with physical installation

Created precise coordination protocols for construction and technical elements

Developed testing and calibration procedures for multimedia components

Established maintenance and troubleshooting documentation

Results & Organizational Impact

This experience developed my ability to manage complex, multi-stakeholder projects where technical constraints, budget realities, and creative vision must be balanced—skills directly applicable to UX projects involving multiple development teams, stakeholders, and technical platforms.

Project Delivery:

Successful completion of complex 5-month multi-phase project

50% cost reduction through strategic process redesign

Maintained artistic integrity while achieving technical optimization

On-time delivery despite significant mid-project strategic changes

Process Innovation:

Created reusable vendor evaluation framework for complex fabrication projects

Developed cost-benefit analysis methodology for strategic decision-making

Established quality assurance protocols for large-scale manufacturing

Built stakeholder communication framework for complex multi-institutional projects

Team Development:

Enhanced cross-functional collaboration between creative and technical teams

Improved vendor relationship management capabilities

Developed agile project management competencies for complex pivots

Created knowledge documentation for technical integration processes

Organizational Capabilities:

Demonstrated strategic flexibility in response to project constraints

Improved cost optimization processes for future projects

Enhanced technical integration capabilities

Strengthened vendor management and relationship building