CASE STUDY:

Rammed Earth

Scaling Complex Cross-Functional Operations in Unique Project Environments

THE CHALLENGE

Create 3 Large Scale Rammed-Earth Pedestals in a Museum Environment

In 2022, for Kelly Akashi, Formations my team was tasked with creating 3 large-scale rammed earth pedestals as display fixtures for her glass and bronze sculptures. This project required specialized materials and equipment, and coordination of multiple teams across different locations. A space-specific coordinated workflow system had to be created—all with limited process documentation.

I managed a 10-person team, including 3 external specialists, across the multi-floor operation. Each team member brought different expertise and constraints, requiring careful coordination to ensure seamless handoffs and maintain quality standards. I led material sourcing, operational design and critical components of the in-house execution of these monolithic concrete pedestals. Importantly, these pedestals made up only one component of the actual exhibition.

Research and Requirements Management

Rammed earth requires a mix of 90% soil —sifted through a giant machine —combined with 10% Portland Cement. I needed to source a supplier that would be willing to manufacture 5 tons of this soil blend. The precise technical specifications combined with specialized materials made this project difficult through standard channels.

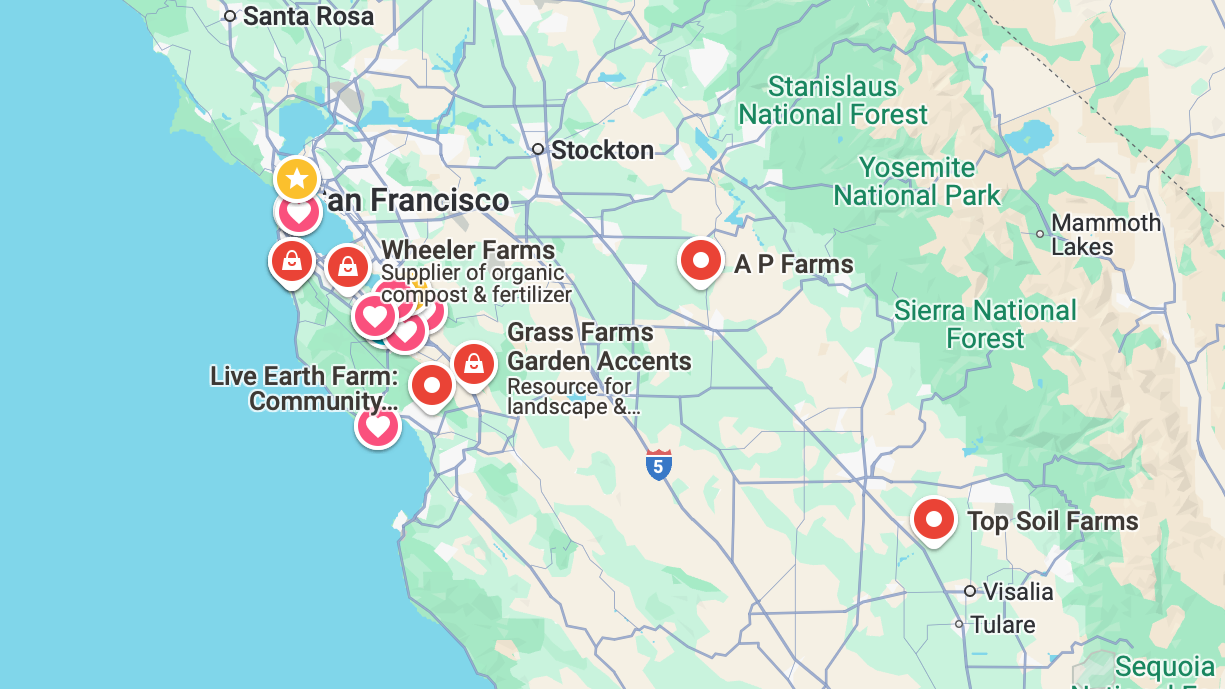

This immediately expanded the scope of my search requiring extensive vendor research and custom solutions. I evaluated over 20 different vendors across California. As a primary example of how tenuous these specialized and unique art installation projects can be, only 1 of those 20 vendors could meet the requirements. Most were unwilling, unable, or lacking the necessary equipment to facilitate our needs.

Process Design & Workflow Optimization

Operational System Design

As our plan came into focus, we realized there were some major hurdles with having our 5 tons of soil delivered.

We needed to avoid creating a massive pile on our dock floor that would disable operations and create inefficiencies. Over the course of the monthlong project, we still needed a way to accept deliveries from vendors and art shippers, which required use of the loading dock. After evaluating multiple options—off-site storage with daily transport, multiple supplier runs, and even repurposing a giant cattle watering tank—I proposed renting a dump-truck to use as an on-dock container. This solution was compact, mobile when needed, and allowed us to secure materials and equipment overnight.

Our facility's loading dock limitations required designing a custom material flow from ground level to second-floor installation while minimizing dust and mess from the mixing process. The soil and cement would first need to be processed in a cement mixer in our loading dock before being transported to the second floor gallery where we would need to build the pedestals in place. Once built, we would not be able to move the pedestals due to the weight and fragility of the material.

In order to map out the flow of prepping and processing materials, I created a SketchUp model of the space and equipment. This helped my team visualize the project and plan for potential roadblocks or challenges.

Soil Logistics

The project required transporting approximately 500 heavy 5-gallon buckets of wet soil mix from ground level, up a staircase, and finally to the second floor via freight elevator. Initial solutions for moving these materials were deemed too physically demanding and inefficient.

I designed a streamlined workflow by:

Renting a material lift with a pallet platform to eliminate heavy lifting

Using dollies to roll buckets from the mixing station to the material lift

Adding a ramp to the pallet edge so that dollies could be rolled smoothly

Final Flow:

Dry soil → electric mixer → 5-gallon buckets on dollies → material lift via ramp → dock level → freight elevator → second floor → pouring team. This eliminated lifting buckets more than 6 inches and created an efficient 500+ repetition process.

To manage a 10-person team across 2 floors, it was essential to establish clear communication channels and a real-time coordination system from a central control point.

By positioning operational control at the critical bottleneck — the mixing station— I developed delivery timing protocols and feedback loops that maintained consistent production flow with quality control at each handoff point.

Beyond quality control, it was also critical to manage expectations across multiple internal and external stakeholders. To do this, I set up a schedule for regular updates and proactively communicated roadblocks that surfaced throughout the process. Team members delivering buckets to the pouring team upstairs were sent with specifics on the flow rate at the mixing station, allowing pace adjustments to keep both teams flowing together.

Managing Workflow

This experience developed my ability to systematically manage complexity, uncertainty, and cross-functional collaboration—skills that directly translate to designing user experiences in ambiguous problem spaces where established patterns don't exist.

Results & Impact

Delivery Success:

Ahead of schedule delivery despite first-time process complexity

Zero safety incidents throughout 3-week intensive rammed earth operation + 8 weeks of broader project

100% quality compliance with technical specifications and aesthetic requirements

Process Innovation:

Created reusable operational framework for similar complex installations

Developed scalable workflow documentation for future projects

Established vendor evaluation criteria for specialized requirements

Team Performance:

Maintained high team performance throughout physically demanding 3-week operation

Successful integration of external specialists with internal team

Effective resource utilization with no material waste or timeline delays