CASE STUDY:

Immersive Light Grid

Managing Complex Technical Projects Through Organizational Change

THE CHALLENGE

Leading Long-Term Cross-Functional Operations

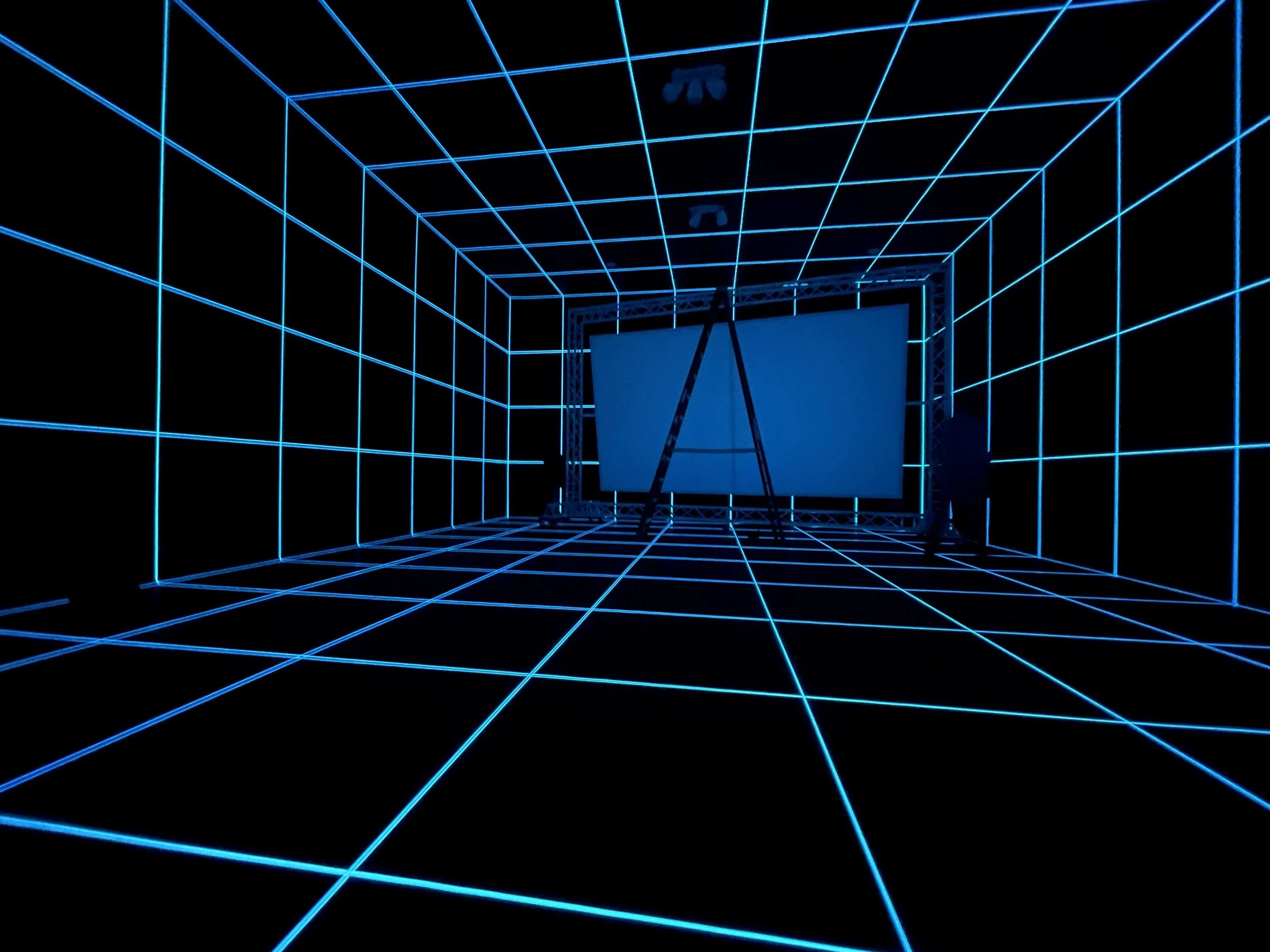

In 2020, my team was tasked with designing and building an immersive theater experience for German artist Hito Steyerl’s Factory of the Sun, a video piece screened in a rubber-lined black box theater with a luminous blue LightTape grid on all sides, and a 16’ x 9’ screen on a tilting arbor.

While we have built many black box theater spaces, the skills and expertise required to create such a specific environment tested every assumption I had about project management. What started as a highly complex installation requiring specialized materials and custom processes quickly became an exercise in adapting to constant change while keeping multiple teams aligned across different locations.

RESEARCH-DRIVEN STRATEGY

Building Knowledge Systems for Complex Projects

Since we were venturing into uncharted territory, I knew we needed to learn from others who had tackled versions of this installation. I traveled to Chicago to meet with the design team at the Museum of Contemporary Art to see their version of the project and to understand their production methodologies and technical solutions. While the experience of stepping into this futuristic environment is similar each time the piece is displayed, the process of sourcing, fabricating, and installing the specialized theater is unique to each institution’s buildings, spaces, and resources.

Strategic Planning & Research

The operational complexity was significant from the start—we were building custom technical systems that required specialized expertise, managing multiple vendor relationships with intricate supply chain dependencies, and coordinating teams that spoke different professional languages (technical and creative disciplines). As a long-term project, we also had to navigate multiple organizational changes, evolving safety protocols, and shifting budget constraints.

Managing Through Adversity

In the midst of planning, the COVID-19 pandemic hit and everything changed overnight. Supply chains that had been reliable for years suddenly became unpredictable. Vendors faced capacity limitations and delivery delays cascaded through our entire timeline. Safety requirements evolved mid-project, forcing us to redesign processes we'd already tested and approved.

Because of shifting safety protocols and the fact that we are a city-owned facility meant that we went through 6 different architectural iterations for the space—taking into account things we never needed to address before, like airflow in a closed theater space, adding filtration systems, and proper spacing of theater seating to accommodate social distancing.

Adaptive Workflow

My approach became about building flexibility into rigid systems. When material specifications changed unexpectedly, I developed modular processes that could accommodate variations without starting from scratch. I established weekly check-in frameworks with vendors that kept distributed teams informed of our changing needs in real-time while also keeping our project top-of-mind for all of our vendors.

For my internal stakeholders, I established regular cross-team check-ins that weren't just status updates—they were collaborative problem-solving sessions. We all worked together in these sessions to discuss and adapt to changing spaces, manufacturing and delivery delays, lack of clarity from stakeholders, and systemic design and logistics challenges. This allowed both technical and creative team members to surface issues before they became critical.

When vendor delays threatened our timeline, I identified tasks that could run in parallel versus those with true dependencies. This kept us on track despite weeks-long material delays.

Process Design & Risk Management

A major component challenge we faced was fabricating the wall panels. The theater’s walls and floor had to be covered with rubber sheets, which were glued to plywood panels and installed like drywall. I learned from the MCA that the glue they used was very toxic and posed a health risk for their team.

We initially considered outsourcing panel production to a contractor with proper ventilation capacity. However, as the pandemic continued, costs skyrocketed and managing a separate timeline and delivery became a burden on our flexible approach. To avoid delays and stay within budget, I researched over 30 non-toxic adhesives for bonding rubber to wood, tested 4, and chose the strongest option, allowing us to safely tackle panel production in-house.

Takeaways

By shifting to a fully in-house process, we eliminated variables, increased productivity, and advanced the project despite supply chain and vendor delays.

Cut panel production costs by more than 50% and timeline by 1 month

Put the team back in full control of timeline and approach

Reorganized the project workflow to allow for continued work during extended vendor timelines

Adapting for the Future

This experience fundamentally changed how I approach complex projects. I learned to design for uncertainty from the beginning, building adaptability into processes rather than treating change as an exception. These skills translate directly to UX work, where user needs, technical constraints, and business priorities are constantly evolving, requiring flexible systems that can respond to change without breaking.

Team Leadership & Stakeholder Management

Cross-Functional Team Coordination:

Led technical team through specialized system design and implementation

Managed stakeholder expectations across 2.5-year timeline

Created communication frameworks for complex technical decisions

Developed training protocols for specialized installation procedures

Adaptive Project Management:

Implemented flexible project management approach responsive to changing conditions

Created rapid decision-making processes for time-sensitive issues

Established regular retrospectives and process improvement cycles

Built organizational knowledge retention systems

Change Management:

Navigated organizational protocol changes during project lifecycle

Adapted workflows to accommodate new safety requirements

Maintained team morale and productivity during uncertain periods

Created scalable processes that survived organizational transitions

Technical Innovation & Problem Solving

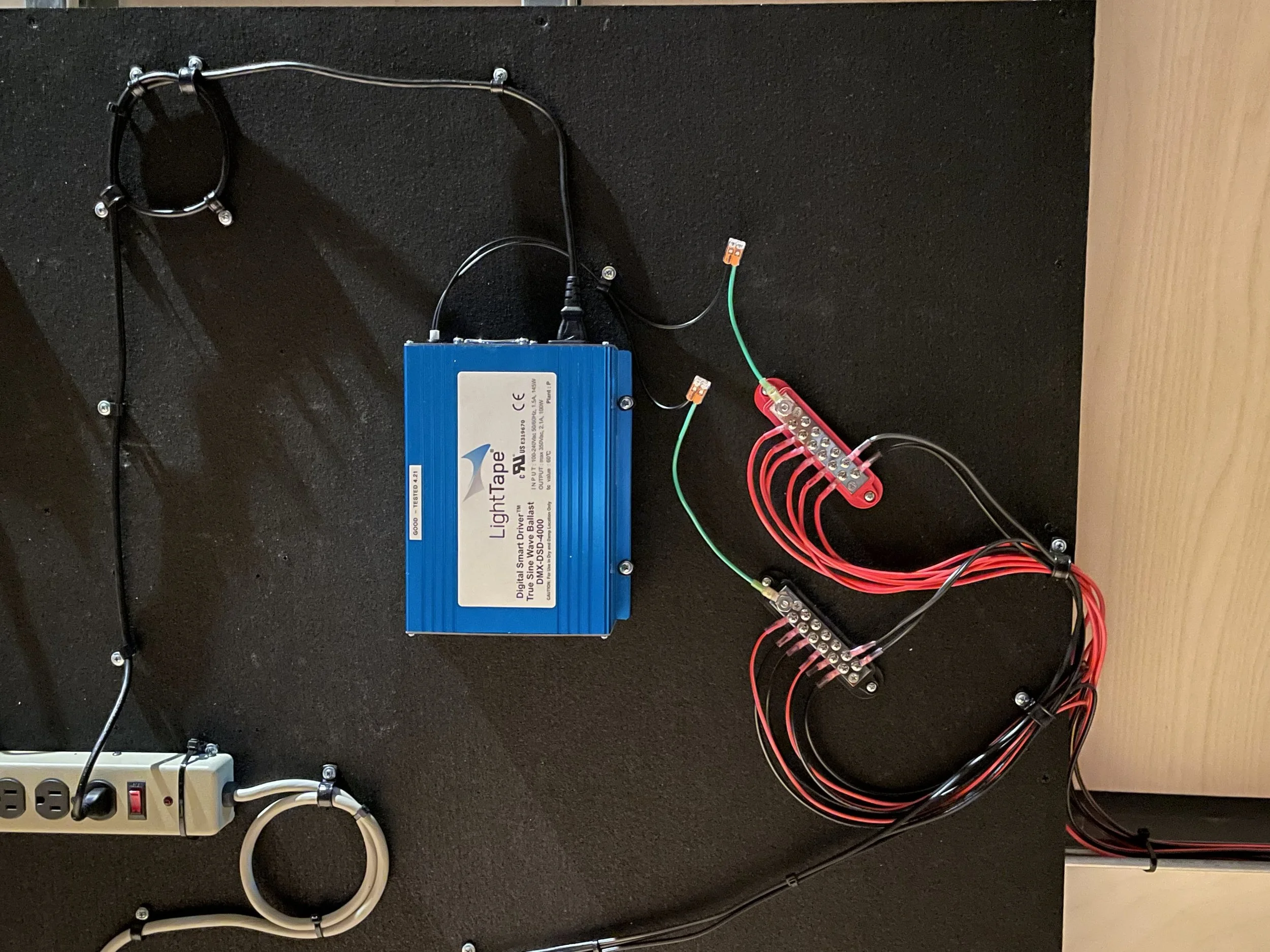

Another significant component hurdle was producing the complex electroluminescent lighting system, which had to be wired and installed in-house. Because each strip of LightTape required its own wiring, I had to create a meticulously organized system to avoid wires getting crossed, tangled, or otherwise damaged. Treating the behind-the-scenes power grid as meticulously as if it were on display was a critical aspect for proper organization, troubleshooting, and smooth installation.

Process Optimization:

Knowing the project had many variables that grew daily due to the pandemic, I focused on simplifying the electrical system's production. By carefully completing each step, the electrical rollout went smoothly and project time was cut by 30% through more efficient workflows. I even made reusable templates, and created a comprehensive installation guide to speed up future projects and set up systems to preserve technical knowledge, helping the team with projects beyond this installation.

Built for Success:

Our architectural design for the theater had access hallways behind 2 walls to facilitate installation of the power system. Five power banks, each on its own breaker, and over 100 electroluminescent tape lines were connected to bus blocks and then to power inverters. Without this access hall, this project would not have been possible.

Safety Through Clarity

The design of the electrical system not only made installation more efficient, but also proved to be a critical safety step. I set up strict safety rules for the low-voltage electrical system to improve reliability and reduce risk, including writing detailed guides for maintenance and troubleshooting to help manage the system and fix problems quickly.

Results & Organizational Impact

Project Delivery:

Successful completion of 2.5-year project despite unprecedented disruptions

Budget optimization achieved through strategic process redesign

Zero safety incidents throughout complex technical production

Exceeded quality standards for specialized technical systems

Process Innovation:

Created reusable operational frameworks still used by organization today

Developed vendor relationship management system improving future project efficiency

Established safety protocols that became organizational standard

Built knowledge documentation reducing future project risk

Increased organizational capacity for future complex projects

Team Development:

Enhanced team capabilities in specialized technical areas

Improved cross-functional collaboration between creative and technical teams

Developed flexible project management competencies across organization

Created succession planning for complex technical projects

Organizational Resilience:

Demonstrated ability to maintain project continuity through major disruptions

Responsive management approach enabled adaptation to changing requirements

Stakeholder confidence maintained throughout extended timeline